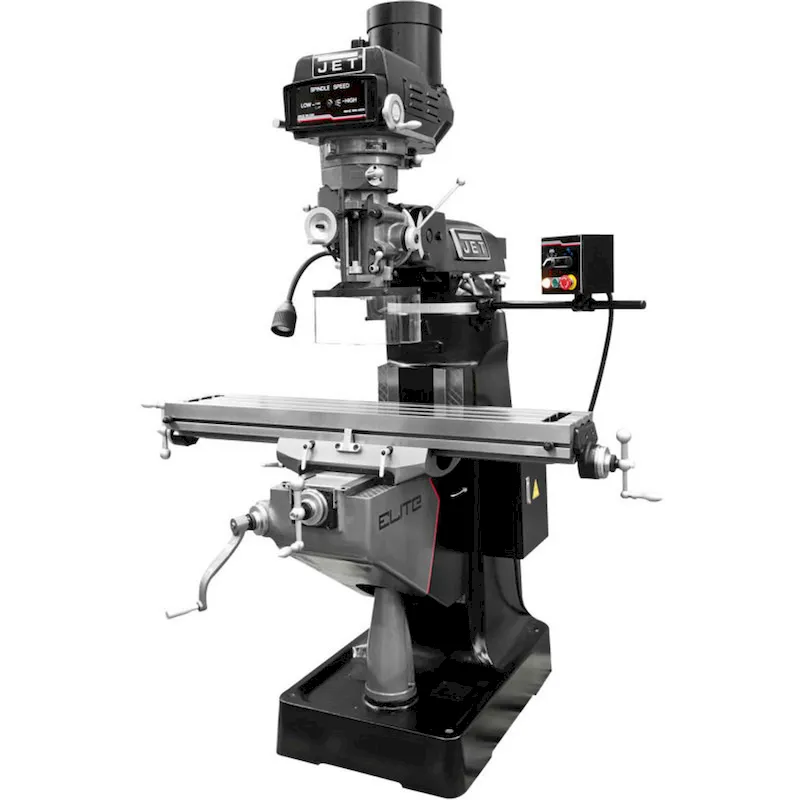

The Jet ETM-949 Mill with 3-Axis ACU-RITE 203 (Knee) DRO (894123) is a professional-grade vertical milling machine engineered for precision, durability, and versatility. Built with robust Meehanite castings and equipped with a powerful 3 HP motor, this mill delivers exceptional performance across various milling applications. The integrated 3-axis DRO system ensures precise positioning and measurement for optimal results.

KEY FEATURES AND BENEFITS:Enhanced Accuracy: Precision angular bearings and a hardened spindle deliver exceptional accuracy for critical machining tasks.Increased Durability: Meehanite castings and a hardened table provide long-lasting performance and resistance to wear.Reduced Backlash: Advanced double nut design ensures smooth, precise movements of the table and saddle.Enhanced Safety: Electronic spindle brake prevents accidental startups, while the automatic lubrication system ensures consistent performance and extends the lifespan of the mill.Improved Efficiency: Variable speed control and a wide range of spindle speeds (60-4500 RPM) allow for optimal machining of diverse materials.Ease of Use: Integrated 3-axis DRO system simplifies operation and ensures accurate measurements.SPECIFICATIONS:Stock Number: JT9-894123Table Size: 9″ x 49″Spindle Taper: R-8Spindle Speeds: 60 – 4,500 RPM (Variable)Quill Diameter: 3-3/8″Motor: 3 HP, 230/460V, 3 PhWeight: 2420 lbsAdditional Specifications: See product manual or manufacturer’s website for full details.HOW TO USE:Preparation: Securely mount your workpiece on the mill table using appropriate clamping devices. Ensure the work area is clean and free of debris.Tool Selection: Select the appropriate milling cutter for your desired operation and securely install it in the spindle.Speed and Feed Adjustment: Set the desired spindle speed and feed rate using the controls on the mill. Consult the material-specific cutting data for optimal settings.Positioning: Use the 3-axis DRO system to precisely position the workpiece and milling cutter for the desired cutting operation.Operation: Begin the milling operation, carefully monitoring the process and adjusting the feed rate or spindle speed as needed.Completion: After the operation is complete, retract the tool, turn off the spindle, and carefully remove the workpiece from the table.BENEFITS OF USING THE Jet ETM-949 Mill with 3-Axis ACU-RITE 203 (Knee) DRO (894123):Produce high-precision parts and components.Achieve consistent and repeatable results.Maximize efficiency with variable speed control and precise positioning.Enjoy reliable and long-lasting performance thanks to robust construction and automatic lubrication.Improve operator safety with the electronic spindle brake.FEATURES:Certified Meehanite CastingsHardened and Ground TableChromium Molybdenum SpindlePrecision Angular BearingsSeamless Steel QuillStainless Steel Y-Axis Way CoverAdvanced Double Nut Design3-Axis ACU-RITE 203 DROElectronic Spindle BrakeAutomatic LubricationPatented Vari-Disc KeyBall Bearing Motor SupportHeat-Treated and Polished Lead ScrewsVariable Speed Pulleys

Reviews

There are no reviews yet.