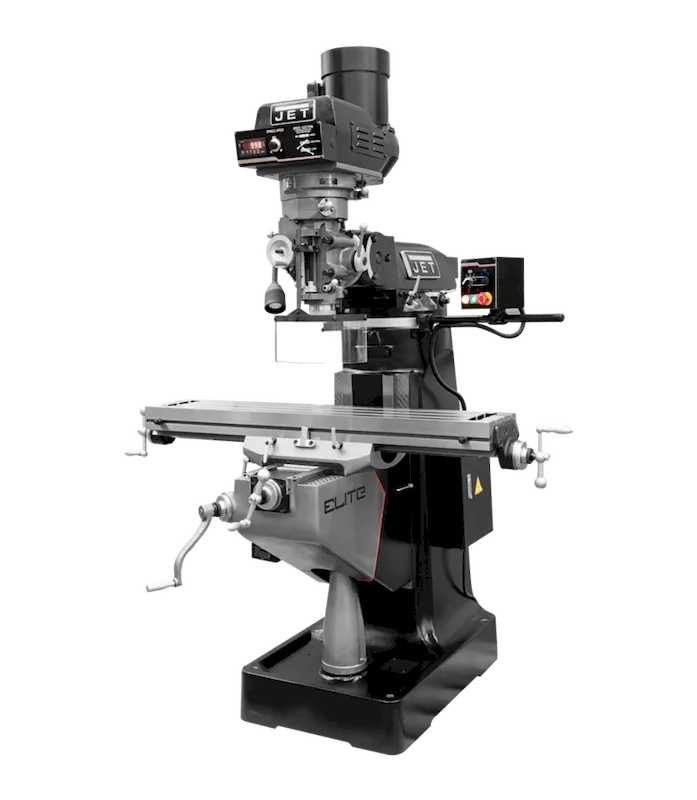

Jet EVS-949 Mill 3-Ax ACURITE 203 (Quill) DRO Servo XYZ Pwrfd (894391) is a high-precision, professional-grade milling machine designed for demanding machining tasks. It is part of Jet’s Elite series, known for its superior quality, performance, and reliability. This mill features a 3-axis ACU-RITE 203 DRO with quill readout, servo power feeds on all axes, and meticulously crafted components to ensure exceptional accuracy and long-lasting performance.

KEY FEATURES AND BENEFITS:Precision Machining: The mill’s spindle utilizes class 7210 (P4, ABEC-7) precision angular bearings, resulting in an industry-leading spindle taper runout of 0.00012″. The Chromium Molybdenum spindle is fully hardened and precisely ground to maintain tight tolerances, ensuring accurate machining results.Durability and Longevity: Hand-scraped ways on the Y and Z axes provide smooth movement and better oil retention, contributing to the mill’s longevity. Heat-treated and polished leadscrews with thrust bearings guarantee smooth, precise table movement under load.User-Friendly Operation: The 3-axis ACU-RITE 203 DRO with quill readout simplifies operation by providing precise measurements and control over the X, Y, Z, and quill axes.Safety Features: The mill is CSA/CUS certified and comes with a spindle safety guard for operator protection. An electronic spindle brake prevents accidental startups, adding another layer of safety.SPECIFICATIONS:Digital Readout: ACU-RITE 203 (Quill)Powerfeed: Servo 150 Series (X, Y, Z)Table Size (L x W): 9″ x 49″Spindle Taper: R-8Quill Diameter: 3-3/8″Spindle Speeds: 60 – 5,000 RPM (Electronic Variable)Quill Down Feed Rates: 0.0015 – 0.003 – 0.006 IPRMotor: 3 HP, 230V, 3 PhOverall Dimensions (L x W x H): 68″ x 63″ x 84″Weight: 2,300 lbsHOW TO USE:Preparation: Ensure the workpiece is securely mounted on the table. Select the appropriate cutting tool and install it in the spindle.Zeroing: Zero the DRO for each axis (X, Y, Z, and quill) using the reference points on the machine.Setting Parameters: Input the desired cutting parameters (speed, feed rate, depth of cut) into the DRO.Operation: Start the spindle and carefully engage the power feeds to begin machining. Monitor the process closely and adjust parameters as needed.Completion: Once the machining is complete, stop the spindle and power feeds. Carefully remove the workpiece and clean the machine.BENEFITS OF USING Jet EVS-949 Mill 3-Ax ACURITE 203 (Quill) DRO Servo XYZ Pwrfd (894391):Increased productivity due to precise and efficient machining.Reduced operator fatigue with servo power feeds.Improved accuracy and repeatability of results.Enhanced safety with CSA/CUS certification and spindle safety guard.FEATURES:Hand-scraped Y and Z-axis waysHeat-treated and polished leadscrewsAutomatic lubrication systemPatented vari-disc key for increased wear resistanceCertified Meehanite® castings for dimensional stability

Reviews

There are no reviews yet.