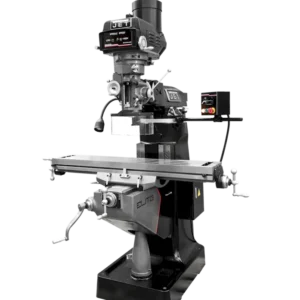

The Jet ETM-949 Mill 3-Axis Newall DP700 (Quill) DRO Servo X-Axis (894223) is a high-performance milling machine designed to meet the demands of professional machinists and workshops. This versatile mill boasts a wide range of features that ensure exceptional accuracy, smooth operation, and long-lasting reliability.

KEY FEATURES AND BENEFITS:Unmatched Accuracy:Precision Spindle Assembly: The ETM-949 features a spindle assembly built with class 7210 (P4, ABEC-7) precision angular bearings, delivering industry-leading spindle taper runout of just 0.00012 inches. This ensures unmatched precision for even the most critical tasks.Hand-scraped Ways: The Y and Z-axis ways are meticulously hand-scraped to a minimum of 16 points per square inch. This time-tested technique promotes superior oil retention and smooth movements, crucial for accurate milling.Digital ReadOut (DRO): The integrated Newall DP700 DRO system provides real-time position data on all three axes (X, Y, and Z). This allows for precise positioning and repeatability, streamlining your workflow.Enhanced Control and Efficiency:Servo X-Axis Powerfeed: The ETM-949 incorporates a servo-controlled powerfeed system for the X-axis. This automated system enables precise and consistent movement along the X-axis, reducing operator fatigue and improving machining consistency.Variable Speed Control: The variable speed motor allows you to adjust the spindle speed from 60 to 4,500 RPM, providing optimal settings for a variety of materials and applications.Durable Construction: Jet has built the ETM-949 to withstand the demands of a busy workshop environment. The mill utilizes certified Meehanite® castings that retain their tolerances and rigidity over time.Additional Features for Operator Safety and Convenience:Spindle Safety Guard: The included spindle safety guard safeguards the operator from accidental contact with the rotating spindle.Automatic Lubrication: The mill features an automatic lubrication system that delivers a precise amount of oil every 30 minutes, ensuring optimal performance and extending machine life.Easy Control Panel: The conveniently located control panel houses all major mill functions and features an emergency stop button for enhanced safety.SPECIFICATIONS:Certified Meehanite® castings for durability and rigidity.Variable spindle speed from 60 to 4,500 RPM.Integrated Newall DP700 DRO system for precise positioning.Servo-controlled powerfeed for X-axis.HOW TO USE:

Follow these steps to use the Jet ETM-949 Mill:

Ensure all safety guards are in place before starting the machine.Adjust the variable speed control to match the material being machined.Use the Servo X-axis powerfeed to automate table movement for efficient cutting.Monitor the Digital ReadOut (DRO) system to maintain accurate positioning.In case of emergency, use the emergency stop button located on the control panel.BENEFITS OF USING Jet ETM-949 Mill 3-Axis Newall DP700 (Quill) DRO Servo X-Axis (894223):Reliable, high-precision milling solution.Exceptional accuracy and advanced features.User-friendly design suitable for any metalworking environment.FEATURES:Wide range of features ensuring exceptional accuracy and reliability.

Reviews

There are no reviews yet.