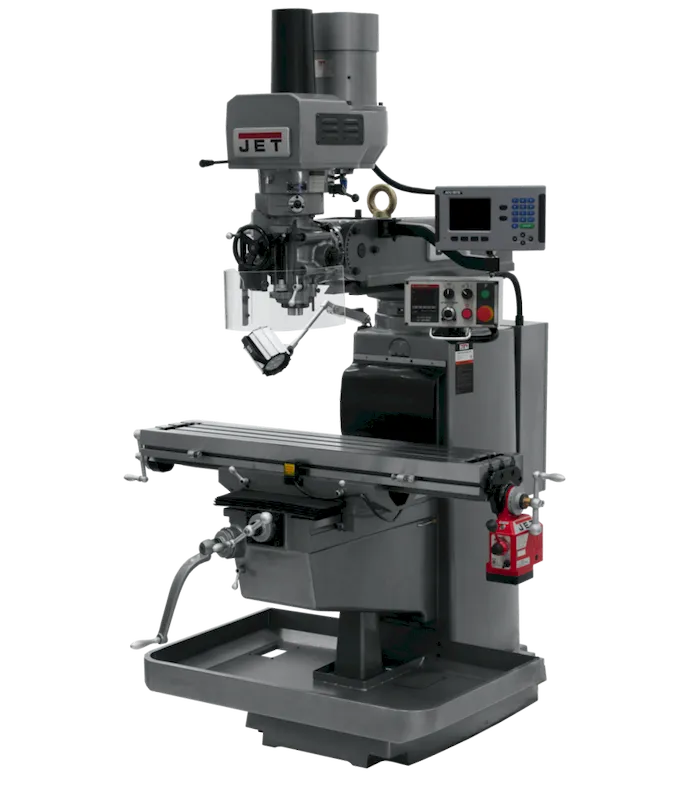

Jet JTM-1050EVS2/230 Mill AcuRite 200S DRO X-Axis Pwrfd APDB (690620)

$24.15

The Jet JTM-1050EVS2/230 Mill AcuRite 200S DRO X-Axis Pwrfd APDB (690620) is a versatile and powerful machine designed for precise metalworking applications. Constructed with certified Meehanite castings, this mill offers a rigid and stable base for accurate results. The innovative design of the column and base allows for easy leveling without lifting the entire machine, saving you time and effort.

KEY FEATURES AND BENEFITS:Variable Speed Control: The electronically controlled variable speed motor allows for spindle speeds ranging from 60 to 4,500 RPM, optimizing cutting performance for various materials.Automatic Lubrication: The automatic oiler provides consistent lubrication at adjustable intervals, minimizing maintenance and extending the machine’s lifespan.X-Axis Powerfeed: Automates the feeding of material during milling operations, enhancing efficiency and reducing operator fatigue.Pneumatic Drawbar: The air-powered drawbar simplifies tool changes, streamlining your workflow and increasing productivity.Acu-Rite 200S DRO: Provides precise positioning and simplifies machining tasks with real-time digital readouts for enhanced accuracy.Heavy-Duty Spindle Brake: Stops the spindle and cuts the power supply in case of emergencies, ensuring operator safety.Swing-Away Safety Shield: Offers additional protection during operation, safeguarding the operator from potential hazards.Relocated Electrical Box: Features built-in 115V outlets for convenient power access for accessories and tools.Toolbox Included: Keeps essential tools organized and readily accessible for quick and easy use.SPECIFICATIONS:Table Size: 10″ x 50″Spindle Travel: 5″Spindle Speeds: Variable, 60 – 4,500 RPMPowerfeed: X-AxisDrawbar: Pneumatic (air-powered)Digital Readout: Acu-Rite 200SMotor: 3 HP, 230V, 3-PhaseOverall Dimensions (L x W x H): 66″ x 63″ x 87″Weight: 2,860 lbsHOW TO USE:Step 1: Position the machine on a stable, level surface and use the built-in leveling system to adjust the base.Step 2: Connect the machine to a 230V, 3-phase power supply for proper operation.Step 3: Set the desired spindle speed using the variable speed control, selecting a range between 60 and 4,500 RPM to match your material and cutting task.Step 4: Secure your workpiece on the 10″ x 50″ table using appropriate clamps to ensure stability during milling.Step 5: Use the Acu-Rite 200S DRO to precisely position your tool on the X, Y, and Z axes for accurate machining.Step 6: Engage the X-axis powerfeed to automate material feeding during milling, reducing manual effort and improving consistency.Step 7: Utilize the pneumatic drawbar for quick and easy tool changes to maintain workflow efficiency.Step 8: Ensure the automatic oiler is functioning to provide consistent lubrication for the machine’s components.Step 9: Use the heavy-duty spindle brake and swing-away safety shield to maintain a safe working environment.BENEFITS OF USING THE Jet JTM-1050EVS2/230 Mill AcuRite 200S DRO X-Axis Pwrfd APDB (690620):High Precision: The Acu-Rite 200S DRO system enhances tool positioning accuracy, ensuring precise and consistent machining results.Improved Efficiency: Features like the X-axis powerfeed and pneumatic drawbar streamline operations, increasing productivity and reducing operator fatigue.Versatile Applications: The variable speed control and spacious worktable accommodate a wide range of materials and milling tasks.Long-Lasting Durability: The robust Meehanite castings and automatic lubrication system contribute to the machine’s longevity and reliability.Enhanced Safety: Safety features such as the heavy-duty spindle brake and swing-away safety shield ensure a secure and safe working environment.Convenient Power Access: The relocated electrical box with 115V outlets provides easy access to power for additional accessories and tools.FEATURES:Meehanite® Cast Iron Base: Provides rigidity and reduces vibrations for accurate milling operations.Variable Speed Control: Allows for precise spindle speed adjustments between 60 and 4,500 RPM to suit different materials and tasks.Acu-Rite 200S DRO: Offers accurate digital readouts for X, Y, and Z axes, improving precision and ease of use.X-Axis Powerfeed: Automates table movement for efficient material feeding and reduced operator effort.Pneumatic Drawbar: Facilitates quick and easy tool changes, enhancing workflow and productivity.5-Inch Quill Travel: Provides flexibility for various workpiece sizes and machining requirements.Safety Features: Includes a heavy-duty spindle brake and a swing-away safety shield for added operator safety.Automatic Lubrication: Maintains consistent lubrication for critical machine components, reducing maintenance needs.LED Work Lamp: Ensures proper lighting for accurate and safe machining operations.Relocated Electrical Box: Features built-in 115V outlets for convenient access to power for accessories and tools.Additional Accessories: Includes a chip pan, way covers, drawbar, and a toolbox with essential tools for comprehensive functionality.

Reviews

There are no reviews yet.