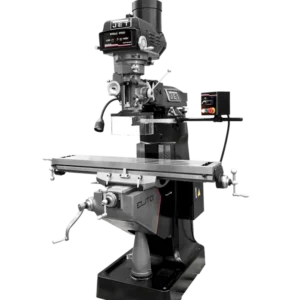

Jet JTM-1254VS Mill w/ NEWALL DP700 3X (Q) DRO & X Powerfeed (698078) is a robust vertical milling machine built for precision and durability. Designed with the professional machinist in mind, it offers a combination of power, accuracy, and user-friendly features. Equipped with a NEWALL DP700 digital readout and X-axis power feed, this machine enhances efficiency and productivity.

KEY FEATURES AND BENEFITSCertified Meehanite Castings: Ensures machine stability and longevity, providing a solid foundation for precise machining.NEWALL DP700 DRO: Offers accurate measurements and control over the machine’s axes for enhanced precision.X-Axis Power Feed: Improves efficiency and productivity by automating the feed movement.Variable Speed: Allows for versatile machining operations by adjusting spindle speed to match different materials and cutting conditions.Automatic Lubrication: Reduces maintenance requirements and extends machine life by providing consistent lubrication.Quick Nut Spindle Feed: Enables easy and rapid depth adjustments.Precision Ground Ways and Table: Ensures smooth and accurate movement of the machine components.SPECIFICATIONSTable Size: 12″ x 54″Spindle Taper: NT40Quill Diameter: 4-1/8″Motor: 5HP, 230/460V, 3PhOverall Dimensions: 92-1/8″ x 79-7/8″ x 104-1/4″Quill Down Feed Rates: .0015–.003–.008 IPRRange of Spindle Speeds: 80 – 3,800 RPMTable Cross Travel: 15-1/3″Table Longitudinal Travel: 33-7/8″Table Longitudinal Travel with Powerfeed: 28-1/4″Work Table Weight Capacity: 925 lbs.Weight: 3969 lbs.HOW TO USESet up the workpiece: Securely clamp the workpiece to the machine table using appropriate clamps and fixtures.Select the right cutting tool: Choose a cutting tool suitable for the material and desired cutting operation.Adjust spindle speed and feed rate: Set the spindle speed and feed rate according to the material and cutting conditions.Zero the DRO: Ensure accurate measurements by zeroing the digital readout before starting the machining process.Perform the machining operation: Carefully guide the cutting tool to create the desired shape or feature.Monitor the cutting process: Observe the cutting process for any signs of tool wear or chatter.Coolant application: Apply coolant if necessary to prevent overheating and improve tool life.Clean the machine: Remove chips and debris after completing the machining operation.BENEFITS OF USING Jet JTM-1254VS Mill w/ NEWALL DP700 3X (Q) DRO & X PowerfeedIncreased productivity: Due to X-axis power feed and variable speed capabilities.Improved accuracy: With NEWALL DP700 DRO and precision ground components.Reduced downtime and maintenance costs: Through automatic lubrication.Versatile machining capabilities: For a wide range of applications.Durable construction: For long-lasting performance.FEATURESCertified Meehanite castingsPrecision bored and honed milling headHigh precision Class 7 spindle bearingsQuick spindle feed nutThree-stage power downfeed with automatic stopHeavy-duty spindle brakePrecision hardened and ground ways and tableThree precision ground t-slotsTurcite B on X & Y axisAdjustable gibs throughoutCSA/CUS certifiedSpindle guardSpindle brakeAutomatic lubricationQuick nut for spindle feedJET exclusive new castingTwo 115V outlets for power feedsSpindle safety guardLED machine lampDual locks on all moveable surfacesChip panDraw barTool box with tools

Reviews

There are no reviews yet.