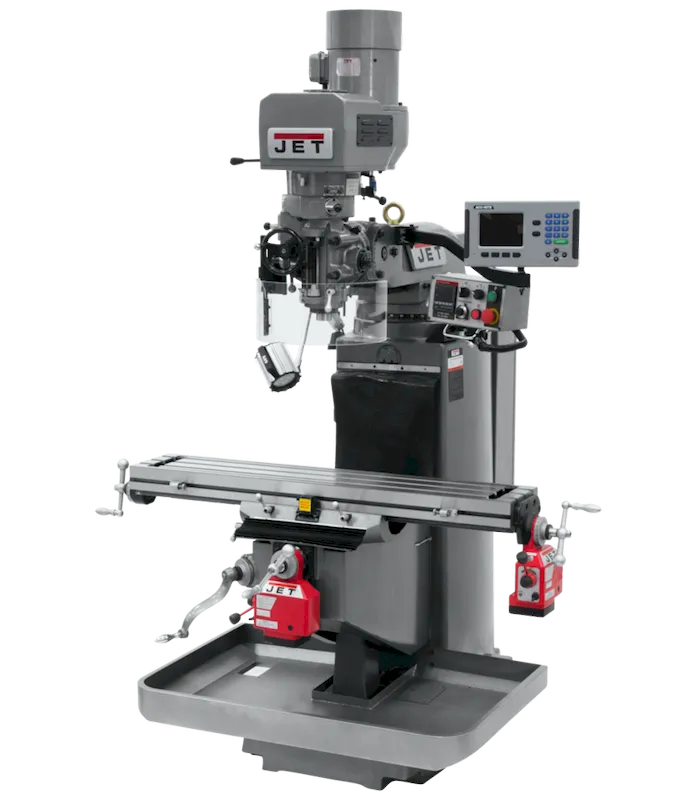

Jet JTM-949EVS Mill 3-Axis Acu-Rite 200S DRO X & Y Powerfeeds (690532)

$23.10

The Jet JTM-949EVS Mill 3-Axis Acu-Rite 200S DRO X & Y Powerfeeds (690532) is a versatile and high-performance vertical milling machine designed for precise metalworking applications. Constructed with a rigid Meehanite casting base, it offers exceptional stability and vibration dampening for accurate machining results. The variable speed spindle motor and electronic controls allow for fine-tuning performance to match various materials and cutting requirements.

KEY FEATURES AND BENEFITSRigid Construction: Meehanite casting with enhanced ribbing minimizes deflection and ensures long-lasting precision.Variable Speed Spindle: Delivers a wide range of speeds (60-4,500 RPM) for optimal performance with different materials and tooling.X & Y-Axis Power Feeds: Automate repetitive movements along the X and Y axes for increased efficiency and operator comfort.Digital Readout (ACU-RITE 200S): Provides real-time position data for all three axes (X, Y, and Quill) for precise control and repeatability.Automatic Oiler: Ensures proper lubrication for smooth operation and extends machine life.Swing-Away Control Panel: Offers easy access to controls and features an E-stop button for enhanced safety.Internally Cooled Spindle Head: Extends bearing, belt, and motor life for reliable performance.Hardened & Ground Table and Ways: Delivers superior flatness and wear resistance for accurate machining.Turcite-B Coated X & Y-Axis: Reduces vibration and ensures smooth table travel for precise cuts.Additional Features: LED work lamp, chip pan, dual locks on movable surfaces, way covers, drawbar, and toolbox with tools.SPECIFICATIONSTable Size (L x W): 9″ x 49″Quill Diameter: 3-3/8″Spindle Speeds: Variable (60 – 4,500 RPM)Quill Feed Rates: .0015 – .003 – .006 in/rev (IPR)Spindle Travel: 5″Head Movement: 90° R & L, 45° F & BMax Distance Spindle to Table: 20-3/4″Collet Capacity: 1/8″ – 7/8″Work Table Weight Capacity: 720 lbs.Motor: 3HP, 230V, 3 PhaseOverall Dimensions (L x W x H): 67 x 64 x 86″Weight: 2,420 lbs.HOW TO USEInstallation: Secure the Jet JTM-949EVS to a stable and level surface. Refer to the user manual for detailed installation instructions.Workpiece Setup: Mount the workpiece securely onto the milling table using clamps or a vise. Ensure proper clearance between the tool and workpiece.Power On and Control Panel: Turn on the machine and familiarize yourself with the control panel layout. Adjust spindle speed, feed rates, and axis positions using the designated controls and digital readout.Tooling Selection: Select the appropriate cutting tool based on the material and desired machining operation (e.g., drilling, milling, facing). Install the tool securely into the spindle taper.Machining: Lower the quill using the handwheel or power feed to bring the cutting tool into contact with the workpiece. Begin machining according to your planned operation.Safety: Always wear appropriate safety gear, including eye protection, gloves, and hearing protection. Be mindful of sharp edges and rotating tools while operating the machine.BENEFITS OF USING Jet JTM-949EVS Mill 3-Axis Acu-Rite 200S DRO X & Y Powerfeeds (690532)Increased Efficiency: Power feeds and variable speed control streamline machining processes.Enhanced Precision: Rigid construction and digital readout ensure accurate results.Improved Productivity: Automated features minimize operator effort and allow for faster completion of tasks.Versatility: Handles a wide range of materials and machining operations.Durability: Built with high-quality components for long-lasting performance.FEATURESMeehanite casting base for rigidity and vibration dampeningVariable speed spindle motor (60-4,500 RPM)X & Y-axis power feedsACU-RITE 200S digital readout for all three axes (X, Y, and Quill)

Reviews

There are no reviews yet.