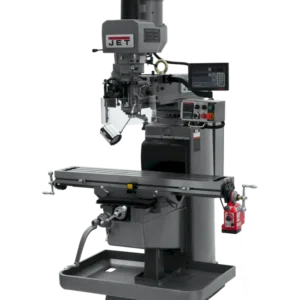

Jet JTM-949EVS Mill with AcuRite 200S 3X (Q) DRO XY Powerfeed (690533)

$25.20

Jet JTM-949EVS Mill with AcuRite 200S 3X (Q) DRO XY Powerfeed (690533) is a versatile and powerful vertical milling machine designed for precise metalworking applications. With its rigid Meehanite® cast iron base and precision-ground table and ways, this mill delivers exceptional accuracy and stability for a wide range of milling tasks.

KEY FEATURES AND BENEFITS:Rigid Construction: Certified Meehanite® casting with enhanced ribbing minimizes deflection for consistent machining results.Variable Speed Control: Spindle speeds from 60 to 4,500 RPM allow for optimal cutting parameters for various materials.Digital Readout (DRO): Acu-Rite 200S DRO provides precise positioning and simplifies machine operation.Power Feeds (X & Y-Axis): Automated power feeds in the X and Y-axis ensure smooth and efficient material movement.Automatic Oiler: Automatic lubrication system extends machine life and reduces maintenance needs.Heavy-Duty Spindle Brake: Ensures safety by stopping the spindle and interrupting power during emergencies.Class 7 Spindle Bearings: High-quality bearings provide maximum rigidity for heavy-duty cutting applications.Internally Cooled Spindle Head: Extends bearing, belt, and motor life for long-lasting performance.Spacious Work Table: 9″ x 49″ table size accommodates a variety of workpieces.Easy Leveling: Innovative machine base design simplifies the leveling process.Swing-Away Control Box: Provides easy access to controls and features an E-stop button for added safety.Multiple Features: LED work lamp, chip pan, dual locks, way covers, drawbar, toolbox with tools, and more.SPECIFICATIONS:Digital Readout: ACU-Rite 200S (3-axis)Powerfeeds: X and Y-AxisPower Draw Bar: PneumaticTable Size (L x W): 9 x 49 in.Quill Diameter: 3-3/8 in.Spindle Speeds: Variable, 60 – 4,500 RPMQuill Travel: 5 in.Head Movement: 90° R & L, 45° F & BMax Distance Spindle to Table: 20-3/4 in.Table Longitudinal Travel: 36 in. (30-3/4 in. with powerfeed)Table Cross Travel: 12-5/8 in.T-Slots: 3, 5/8″ wideCollet Capacity: 1/8″ – 7/8″Motor: 3 HP, 230V, 3-PhaseOverall Dimensions (L x W x H): 67 x 64 x 86 in.Weight: 2,420 lbs.HOW TO USE:Installation: Securely mount the mill on a stable and level surface. Follow the manufacturer’s instructions for proper installation and electrical connection.Workpiece Setup: Clamp your workpiece securely to the mill table using a vise or T-slot clamps. Ensure proper alignment and clearance.Tooling Selection: Select the appropriate cutting tool (end mill, drill bit, etc.) based on the material and desired machining operation. Install the tool securely in the spindle using the drawbar.Speed and Feed Selection: Refer to the cutting tool manufacturer’s recommendations and material specifications to set the appropriate spindle speed and feed rate using the controls on the machine.Operation: Engage the spindle motor and power feeds (if desired) to begin machining. Use the handwheels or DRO to control the movement of the table and quill for precise positioning.Safety: Always wear appropriate safety gear, including eye protection, gloves, and proper clothing. Be mindful of sharp edges and rotating machinery during operation.BENEFITS OF USING Jet JTM-949EVS Mill with AcuRite 200S 3X (Q) DRO XY Powerfeed (690533):Increased Productivity: Power feeds and variable speed control allow for faster and more efficient machining compared to manual operation.Enhanced Accuracy: Rigid construction and digital readout ensure precise positioning and consistent results.Versatility: Handles a wide range of milling tasks on various materials.Durability: Built with high-quality components for long-lasting performance and minimal maintenance requirements.Improved Ergonomics: Swing-away control box and easy-to-access features provide a comfortable and efficient working environment.Safety Features: Automatic oiler, heavy-duty spindle brake, and E-stop button prioritize operator safety.FEATURES:Certified Meehanite® casting for rigidity and accuracy retentionSwing-away control box with E-stop button for easy accessInnovative machine base design for easier levelingAutomatic oiler (3-6 cc/cycle every 30 minutes)Heavy-duty spindle brake for safetyRelocated electrical box with 2 x 115V outlets for accessoriesCSA/CUS CertifiedClass 7 spindle bearings for maximum rigidityInternally cooled spindle head for extended bearing and motor lifeTable and ways hardened to 54 HRC and precision ground for accuracyTurcite-B coated X and Y-axis for reduced vibration and smooth movementsSwing-away safety shieldLED work lamp for improved visibilityChip pan for easy waste collectionDual locks on all moveable surfaces for stabilityWay covers for protecting linear waysDrawbar for quick and easy tool changesToolbox with tools for added convenience

Reviews

There are no reviews yet.