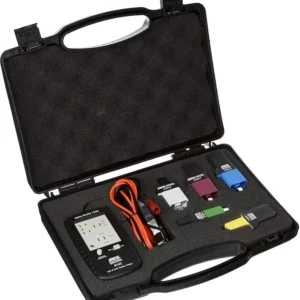

Soartec Air Diesel Engine Injector Removal Puller (WS-406)

$237.30 Original price was: $237.30.$59.33Current price is: $59.33.

The Soartec Air Diesel Engine Injector Removal Puller (WS-406) is a specialized pneumatic tool engineered to facilitate the safe and effective removal of seized diesel fuel injectors from engine blocks. Over time, injectors can become heavily carbonized or corroded, making manual extraction extremely difficult and often damaging. The WS-406 addresses this challenge by utilizing controlled pneumatic power and high-frequency impact to loosen and extract these components, significantly reducing the effort and time involved in diesel engine maintenance and repair. This tool is an essential addition for professional mechanics and serious DIY enthusiasts working on diesel engines.

KEY FEATURES AND BENEFITS:Pneumatic Power: Utilizes compressed air to generate strong, consistent force for injector extraction, minimizing physical strain.High-Frequency Impact (3,300 BPM): Delivers rapid blows per minute, which effectively breaks down carbon buildup and rust, helping to free stubborn injectors without excessive force.13 Adapters (M13-M27): Includes a comprehensive set of adapters, ensuring compatibility with a wide range of diesel injector sizes and types across various engine models.Designed for Longer Lifespan: Constructed with a special mechanism aimed at enhancing the tool’s durability and ensuring reliable performance over extended use.Efficient and Time-Saving: Accelerates the injector removal process, allowing technicians to complete tasks more quickly and reduce overall service time.Minimizes Component Damage: Engineered to apply force precisely, reducing the risk of damaging the injector, cylinder head, or surrounding engine components during removal.SPECIFICATIONS:Model Number: WS-406Brand: SoartecBPM (Blows Per Minute): 3300Air Consumption: 7.9 CFMAir Pressure: 90 PSIAir Inlet Size: 1/4″ PTRecommended Air Hose Size: 1/4″Length: 226 mmWeight: 5.2 lbsIncluded in Purchase: 1 Soartec WS-406 Air Diesel Engine Injector Removal Puller, 13 Adapters (M13-M27), and a carrying caseHOW TO USE:Prepare the Engine: Ensure the engine is cool and disconnected from its power source. Remove any surrounding components (e.g., fuel lines, electrical connectors) that obstruct access to the injectors. Clean the area around the injectors to prevent debris from entering the engine.Select Adapter: Identify the correct adapter from the supplied set that securely threads onto the top of the injector to be removed.Attach Adapter to Injector: Carefully thread the chosen adapter onto the injector. Ensure it is fully engaged and hand-tight.Connect Tool: Attach the Soartec WS-406 puller tool to the adapter.Connect Air Supply: Connect a regulated air supply hose (1/4″ recommended) to the tool’s 1/4″ PT air inlet, ensuring the air pressure is set to 90 PSI.Operate Tool: With a firm grip on the tool, activate the trigger or lever. The pneumatic hammer will begin delivering rapid impacts, gradually loosening the injector.Monitor Progress: Apply steady, upward pressure while the tool operates. The injector should begin to move. Continue until the injector is fully extracted.Repeat as Needed: For engines with multiple injectors, repeat the process for each injector.Clean Up: Once all injectors are removed, clean the injector bores and prepare for installation of new or serviced injectors. Disconnect the air supply and store the tool and adapters in their case.BENEFITS OF USING SOARTEC AIR DIESEL ENGINE INJECTOR REMOVAL PULLER (WS-406):Facilitates the removal of severely seized or stuck diesel injectors that are otherwise challenging to extract.Reduces the physical effort and strain on the technician compared to manual or slide hammer methods.Helps prevent costly damage to delicate cylinder head components and the injectors themselves during removal.Significantly decreases diagnostic and repair time in diesel engine servicing operations.Provides a professional solution for common diesel engine maintenance tasks, enhancing workshop efficiency.Its specialized design ensures reliable performance and longevity, making it a valuable long-term investment.FEATURES:Integrated pneumatic hammer delivers high-frequency impacts for controlled injector loosening.Adapter system supports thread-on compatibility with a wide range of injector types.Standard 1/4″ PT air inlet offers broad compatibility with existing pneumatic systems.Compact body design allows easy maneuverability within engine bays with limited space.Durable construction engineered for tough workshop conditions and long service life.Comfortable grip for better handling and control during extended use.Includes organized carrying case for easy storage and transport of tool and adapters.

Reviews

There are no reviews yet.