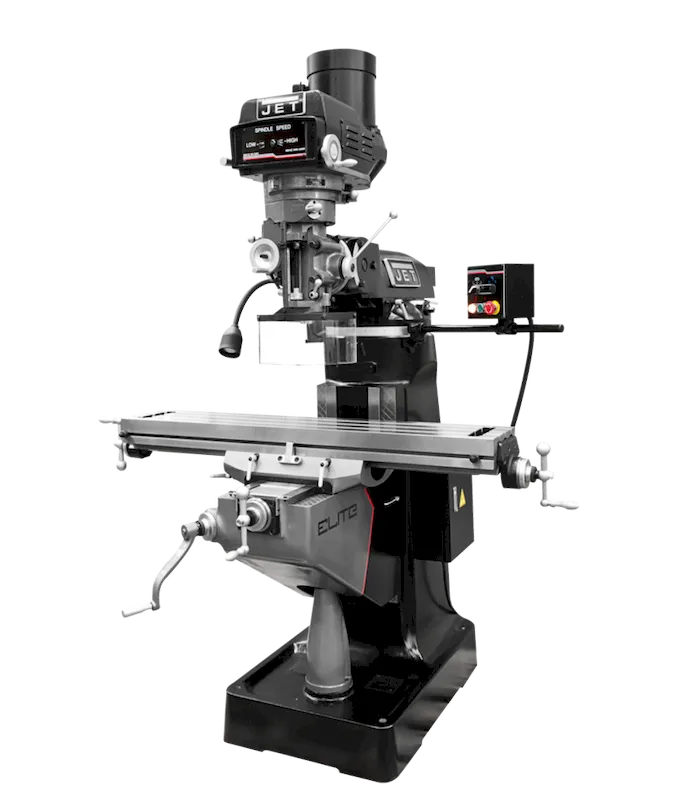

The Jet ETM-949 Mill 3-Axis Newall DP700 (Knee) DRO Servo X-Axis (894230) is a meticulously engineered milling machine designed for professionals who demand precision, durability, and safety. As part of Jet’s Elite series, this mill is built with high-quality components and advanced features to meet the rigorous requirements of demanding machining tasks.

KEY FEATURES AND BENEFITS:Precision and Accuracy:Spindle assembly with an industry-leading spindle taper runout of 0.00012″ ensures exceptional accuracy and consistency.Hand-scraped ways on the Y and Z axes provide smooth, precise movement and enhanced oil retention.Double nut design eliminates backlash for tightly controlled lateral movements.3-axis Newall DP700 Digital Read Out (DRO) system, mounted on the knee, provides precise measurements for accurate machining.Durability and Reliability:Hardened chromium molybdenum spindle and induction-hardened, chromed quill ensure exceptional strength and resistance to wear.Patented vari-disc key offers ten times the wear resistance of traditional keys.Certified Meehanite® castings maintain dimensional stability over years of use.Stainless steel Y-axis way cover adds an extra layer of protection.Safety and Convenience:CSA/CUS certified, meeting rigorous safety standards.Spindle safety guard, electronic spindle brake, and mounted control box with emergency stop button contribute to a safer working environment.Servo X-axis powerfeed and USA-made air-powered drawbar enhance ease of use and efficiency.SPECIFICATIONS:Capacity: 9″ x 49″Spindle taper runout: 0.00012″Hardened chromium molybdenum spindleInduction-hardened, chromed quill3-axis Newall DP700 Digital Read Out (DRO) systemServo X-axis powerfeedUSA-made air-powered drawbarAutomatic lubrication systemCertified Meehanite® castingsStainless steel Y-axis way coverHalogen machine lampDual locks on all surfacesHOW TO USE:Ensure the machine is properly set up and securely mounted.Turn on the automatic lubrication system to ensure the machine is well-lubricated.Select the appropriate spindle speed for your material and operation.Use the servo-driven X-axis power feed to position your workpiece accurately.Engage the spindle and commence milling operations.Monitor the DRO for precise measurements and adjustments.Utilize the spindle safety guard and electronic spindle brake for safety.In case of an emergency, use the emergency stop button to immediately shut down the machine.BENEFITS OF USING Jet ETM-949 Mill 3-Axis Newall DP700 (Knee) DRO Servo X-Axis (894230):Achieve exceptional precision with an industry-leading spindle taper runout.Experience smooth and controlled movements with hand-scraped ways and backlash elimination design.Prolong machine lifespan with automatic lubrication and patented vari-disc key.Ensure long-term rigidity with certified Meehanite castings and stainless steel way cover.Operate safely with CSA/CUS certification and built-in safety features.FEATURES:Industry-leading spindle taper runout of 0.00012″.Hand-scraped Y and Z-axis ways for smooth and precise movement.Double nut design to eliminate backlash.Hardened chromium molybdenum spindle and induction-hardened, chromed quill.Patented vari-disc key with ten times wear resistance.Certified Meehanite® castings for long-term rigidity.Stainless steel Y-axis way cover for superior protection.3-axis Newall DP700 Digital Read Out (DRO) system, mounted on the knee.Servo X-axis powerfeed for enhanced productivity.USA-made air-powered drawbar.Automatic lubrication system for worry-free maintenance.Halogen machine lamp for optimal visibility.Dual locks on all surfaces for added security.CSA/CUS certification for stringent safety guidelines.Spindle safety guard and electronic spindle brake.Emergency stop button on the control box.

Reviews

There are no reviews yet.