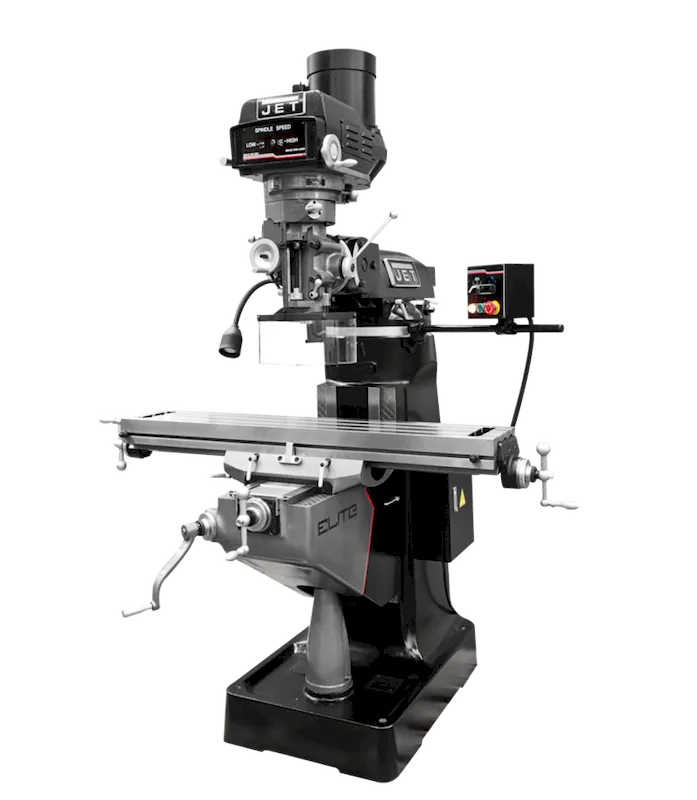

The Jet ETM-949 Mill with 2-Axis ACU-RITE 203 DRO XYZ Powerfeeds (894115) is a high-performance milling machine designed for machinists and hobbyists who demand precision and reliability.

KEY FEATURES AND BENEFITS:Unmatched Precision:Industry-leading spindle taper runout of 0.00012″ thanks to class 7210 (P4, ABEC-7) precision angular bearings.Fully hardened Chromium Molybdenum spindle maintains strict tolerances for consistent results.Hand-scraped ways on the Y and Z-axis ensure smooth movements and optimal oil retention.Built to Last:Certified Meehanite® castings retain their shape and rigidity over time.Seamless, one-piece steel quill offers increased strength and precision.Automatic lubrication system extends machine life.Stainless steel Y-axis way cover provides superior protection.Enhanced Functionality:Variable speed control (60-4,500 RPM) allows for adapting to various materials.X, Y, and Z-axis JET powerfeeds automate movements for efficient operation.2-axis ACU-RITE 203 DRO provides digital readouts for X and Y positions.Advanced double nut design eliminates table and saddle backlash for precise control.Safety Features:Electronic spindle brake prevents accidental startups.Spindle safety guard protects users from debris.Emergency stop button ensures quick machine shutdown.CSA/CUS certified for electrical safety.Ideal for a Wide Range of Applications:Suitable for facing, boring, drilling, pocketing, slotting, contouring, and more.High-precision components, durable construction, and user-friendly features make it a valuable addition to any workshop.SPECIFICATIONS:Digital Readout: ACU-RITE 203 (2-axis)Powerfeed: X, Y, and Z-axisPower Draw Bar: USA MadeTable Size: 9″ x 49″Spindle Taper: R-8Quill Diameter: 3-3/8″Spindle Speeds: Variable (60 – 4,500 RPM)Work Table Weight Capacity: 550 lbs.Overall Dimensions: 68″ x 63″ x 84″Weight: 2420 lbs.Motor: 3 HP, 230/460V, 3-PhaseHOW TO USE:Set up the milling machine on a stable surface.Ensure the workpiece is securely clamped onto the table.Turn on the machine and adjust the variable speed control to match your material and project requirements.Use the 2-axis ACU-RITE 203 DRO to position the spindle accurately.Activate the X, Y, and Z-axis JET powerfeeds to automate movements.Monitor the milling process and make adjustments as needed.Utilize the automatic lubrication system to maintain smooth operation.Use the spindle safety guard and emergency stop button to ensure operator safety.Press the emergency stop button in case of any unforeseen issues.BENEFITS OF USING JET ETM-949 MILL WITH 2-AXIS ACU-RITE 203 DRO XYZ POWERFEEDS (894115):Achieve high-precision milling with tight tolerances.Enhanced positioning accuracy with the ACU-RITE 203 DRO.Reduced operator fatigue and increased productivity with automated movements.Extended machine lifespan due to superior oil retention and lubrication.Increased safety features for operator protection.FEATURES:Precision spindle assembly for accurate milling.Advanced digital readout system for precise positioning.Automated power feeds for effortless control.Durable construction with Chromium Molybdenum spindle.Enhanced oil retention and smooth operation with hand-scraped ways.Variable speed control for material-specific adjustments.Safety features including spindle guard, electronic brake, and emergency stop.

Reviews

There are no reviews yet.