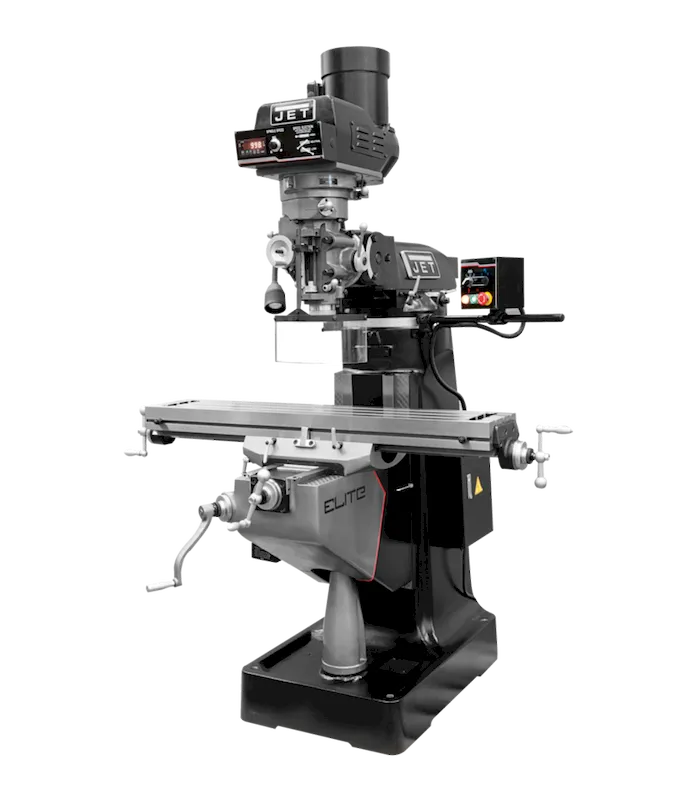

The Jet EVS-949 Mill 2-Axis Newall DP700 DRO XYZ Axis Powerfeed (894357) is a high-performance vertical knee mill designed for precision machining applications. Built with a focus on durability and accuracy, this mill is ideal for professional machinists and metalworking shops.

KEY FEATURES AND BENEFITS:Precision Machining: Features like hand-scraped ways, a fully hardened spindle, and class 7210 precision angular bearings ensure accurate cuts and repeatable results.Durable Construction: Cast iron base and column, Meehanite castings, and a vari-disc key for wear resistance provide long-lasting performance.Operator Safety: CSA / CUS certified with a spindle safety guard for user protection.Enhanced Control: Includes a Newall DP700 digital readout (DRO) for precise positioning and X, Y, and Z-axis power feeds for automated movement of the cutting tool.USA-Made Power Drawbar: Provides reliable tool holding and simplifies tool changes.SPECIFICATIONS:Motor: 3 HP, 230V, 3-phaseSpindle Speed Range: Variable, 60 to 5,000 RPMSpindle Taper: R8Table Size: 9″ x 49″Quill Travel: 5″Maximum Distance Spindle to Table: 18-3/4″Overall Dimensions: 68″ x 63″ x 84″Weight: 2,300 lbsHOW TO USE:Consult the user manual for detailed instructions on installation, calibration, and operation procedures.Ensure the mill is properly set up and aligned according to manufacturer guidelines.Use the Newall DP700 DRO for precise positioning of the cutting tool.Engage the X, Y, and Z-axis power feeds for automated movement during operation.Adjust the spindle speed to match the material being machined for optimal cutting performance.Maintain the automatic lubrication system to ensure smooth operation and extend machine life.Operate the mill safely using the mounted control box with emergency stop button and other safety features.BENEFITS OF USING Jet EVS-949 Mill 2-Axis Newall DP700 DRO XYZ Axis Powerfeed (894357):Increased Precision: Delivers accurate cuts and consistent results for your machining projects.Enhanced Efficiency: Power feeds and digital readout improve speed and control during operation.Heavy-Duty Performance: Built to handle demanding applications with durable construction.Long-Lasting Reliability: Designed with quality materials and components for extended use.Operator Safety: Safety features minimize risk and promote a safe working environment.FEATURES:Hand-scraped ways for smooth operation and oil retentionFully hardened Chromium Molybdenum spindle for strict tolerance requirementsClass 7210 precision angular bearings for industry-leading spindle taper runoutAutomatic lubrication system for smooth operationVariable speed control for optimal cutting speeds on various materialsHardened and ground table for a stable and accurate work surfaceHeat treated and polished lead screws for precise table movementDouble nut design to eliminate table and saddle backlashBall bearing motor shaft support for quiet operationStainless steel Y-axis way cover for added protectionElectronic spindle brake prevents accidental startupsMounted control box with emergency stop button

Reviews

There are no reviews yet.