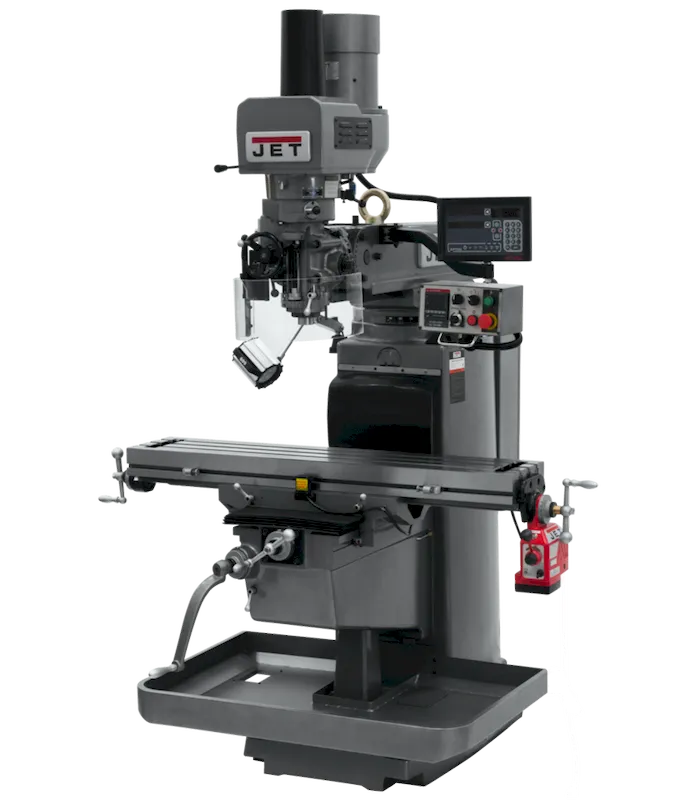

Jet JTM-1050EVS2/230 Mill 3-Axis Newall DP700 DRO KNEE X Prfd (690640)

$25.20

The Jet JTM-1050EVS2/230 Mill 3-Axis Newall DP700 DRO KNEE X Prfd (690640) is a versatile and robust vertical mill designed for accurate and dependable metalworking operations. Constructed with a Meehanite® cast iron base, this machine boasts exceptional rigidity and vibration dampening, ensuring clean cuts and consistent results. The electronic variable speed control allows for fine-tuned operation across a wide range of materials (60 – 4,500 RPM).

KEY FEATURES AND BENEFITS:Enhanced Precision: Equipped with a 3-axis Newall DP700 Digital ReadOut (DRO) that provides real-time positional feedback on the X, Y, and Z axes, enabling precise machining dimensions.Ease of Use: The X-axis powerfeed automates movement along the X-axis, streamlining repetitive tasks and reducing operator fatigue.Operator Safety: Features a swing-away control box for easy access to controls, an emergency stop button for immediate machine stoppage, and a heavy-duty spindle brake that prevents accidental startups.Convenient Setup: The innovative design of the base simplifies machine leveling without lifting, saving valuable time during setup.Durable Construction: Class 7 spindle bearings ensure maximum rigidity during heavy-duty cutting applications, while the internally cooled spindle head extends the lifespan of bearings, belts, and the motor.Consistent Performance: The table and ways are hardened up to 54 HRC and precision ground for exceptional accuracy. The X and Y-axis are coated with Turcite-B to reduce vibration and ensure smooth movement.Improved Visibility: The LED work lamp provides better visibility in the workspace, enhancing precision and safety.Effortless Cleanup: Includes a chip pan for easy chip collection and dual locks on all movable surfaces for increased stability.SPECIFICATIONS:Table Size: 10″ x 50″Speed Range: 60 – 4,500 RPMDigital ReadOut: Newall DP700 3-Axis DROPower Feed: X-axisSpindle Bearings: Class 7Spindle Cooling: InternalTable and Ways Hardness: Up to 54 HRCAxis Coating: Turcite-B on X and Y-axisLubrication: Automatic oilerSafety Features: Heavy-duty spindle brake, emergency stop button, swing-away control boxAdditional Features: LED work lamp, chip pan, dual locks on movable surfacesConstruction: Meehanite® cast iron for rigidity and vibration dampeningHOW TO USE:Setup: Place the milling machine on a stable surface and ensure it is level without lifting.Power On: Connect to the power supply and switch on the machine.Adjust Speed: Use the electronic variable speed control to set the desired RPM for your specific task.Secure Workpiece: Position and secure the workpiece on the 10″ x 50″ table.Tool Positioning: Use the Newall DP700 DRO to position the cutting tool accurately.Engage Power Feed: Activate the X-axis powerfeed to automate table movement.Start Milling: Begin the milling operation, ensuring to monitor the process and make adjustments as necessary.Tool Change: Use the drawbar to change tools when needed.Safety Check: Utilize the safety features such as the spindle brake and emergency stop button as needed.Cleanup: After milling, use the chip pan to collect and dispose of metal shavings, and perform routine maintenance.BENEFITS OF USING Jet JTM-1050EVS2/230 Mill 3-Axis Newall DP700 DRO KNEE X Prfd (690640):High Precision: The Newall DP700 DRO system ensures accurate positioning and repeatability.Durable Construction: Meehanite® cast iron base and Class 7 spindle bearings provide long-lasting performance.Enhanced Safety: Features like the emergency stop button and heavy-duty spindle brake ensure operator safety.User Convenience: Automatic oiler and power feeds streamline operation and maintenance.Efficient Workflow: The spacious table and quick tool changes enhance productivity and efficiency.Stable Operation: Dual locks on movable surfaces and hardened components ensure stability during use.FEATURES:Rigid Construction: Built with Meehanite® cast iron for exceptional rigidity and vibration dampening.Variable Speed Control: Allows for precise spindle speed adjustment from 60 to 4,500 RPM.Precise Digital ReadOut: Equipped with the Newall DP700 3-Axis DRO for accurate positioning.Automated Table Movement: X-axis powerfeed automates table movements for efficiency.Spacious Worktable: 10″ x 50″ table provides ample space for various workpieces.Tool Changes: Drawbar facilitates quick and easy tool changes.Extended Component Life: Internal spindle cooling and automatic oiler for longevity.Safety First: Features include a heavy-duty spindle brake, emergency stop button, and swing-away control box.Improved Visibility: LED work lamp for better visibility during operations.Effortless Cleanup: Chip pan for easy waste management.Stable and Secure: Dual locks on movable surfaces enhance stability and safety.

Reviews

There are no reviews yet.