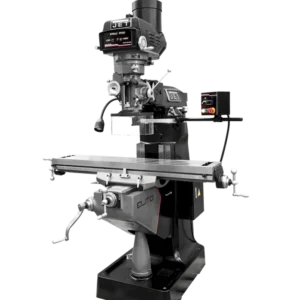

Jet JTM-1254VS Mill w/ACU-RITE 203 DRO XY Pwrfds & APD (698052) is a heavy-duty vertical milling machine designed for precision and efficiency. It features a 12″ x 54″ table size, NT40 spindle taper, and a variable speed range of 80-3,800 RPM. The machine includes ACU-RITE 203 DRO for accurate measurements, X & Y power feeds for automated table movement, and an air power drawbar for quick tool changes.

KEY FEATURES AND BENEFITS:ACU-RITE 203 DRO: Provides precise measurements for accurate work.X & Y Power Feeds: Increases productivity and efficiency through automated table movement.Air Power Drawbar: Allows for quick and easy tool changes, saving time.Variable Speed: Offers a wide range of spindle speeds to accommodate various cutting tasks.Automatic Lubrication: Reduces maintenance and extends the machine’s life.Quick Nut Spindle Feed: Enables efficient operation.SPECIFICATIONS:Table size: 12″ x 54″Spindle taper: NT40Spindle speed range: 80-3,800 RPMMotor power: 5 HP, 230/460V, 3PhQuill diameter: 4-1/8″Quill down feed rates: .0015, .003, .008 IPRSpindle travel: 5″Head movement: 90° R & L, 45° F & BMax distance spindle to table: 23″Distance spindle to column (max.): 27-3/4″Distance spindle to column (min.): 7-1/2″Collet capacity: 1/8″ – 1″Table longitudinal travel: 33-7/8″Table longitudinal travel with power feed: 28-1/4″Table cross travel: 15-1/3″T-slot centers: 2-1/2″Work table weight capacity: 925 lbsTravel of knee: 19-1/4″Travel of ram: 25″Saddle width: 25-5/8″Column width: 14-1/4″Prewired: 230V (surcharge applies for 460V re-wire)Overall dimensions: 92-1/8″ x 79-7/8″ x 104-1/4″Weight: 3969 lbsHOW TO USE:Set up the workpiece: Securely clamp the workpiece to the milling machine table using appropriate clamps and fixtures.Select the correct cutting tool: Choose a cutting tool that matches the material being machined and the desired cutting parameters.Adjust spindle speed: Set the spindle speed to an appropriate value based on the material and cutting tool.Position the tool: Use the DRO and power feeds to accurately position the cutting tool relative to the workpiece.Engage power feed: Turn on the power feed to automatically move the table or workpiece during the cutting process.Start the machine: Turn on the spindle and begin the cutting operation.Monitor the cutting process: Observe the cutting process for proper chip removal and tool wear. Make adjustments as needed.Turn off the machine: Once the cutting process is complete, turn off the spindle and power feed.Unclamp the workpiece: Carefully remove the workpiece from the machine table.BENEFITS OF USING Jet JTM-1254VS Mill w/ACU-RITE 203 DRO XY Pwrfds & APD (698052):Improved precision and accuracy: The ACU-RITE DRO and power feeds enable precise control over the cutting process.Increased productivity: Automated table movement and quick tool changes enhance efficiency.Versatility: The variable spindle speed and various cutting tools allow for a wide range of applications.Durability and reliability: The heavy-duty construction and automatic lubrication ensure long-lasting performance.Ease of use: User-friendly features and controls simplify operation.FEATURES:Certified Meehanite castingsPrecision bored and honed milling headHigh-precision Class 7 spindle bearingsQuick spindle feed nutThree-stage power downfeed with automatic stopHeavy-duty spindle brakePrecision hardened and ground ways and tableThree precision ground t-slotsTurcite B on X & Y axisAdjustable gibs throughoutCSA/CUS certifiedSpindle guardSpindle brakeAutomatic lubricationQuick nut for spindle feedJET exclusive new castingTwo 115V outlets for power feedsSpindle safety guardLED machine lampDual locks on all moveable surfacesChip panDraw barTool box with tools

Reviews

There are no reviews yet.